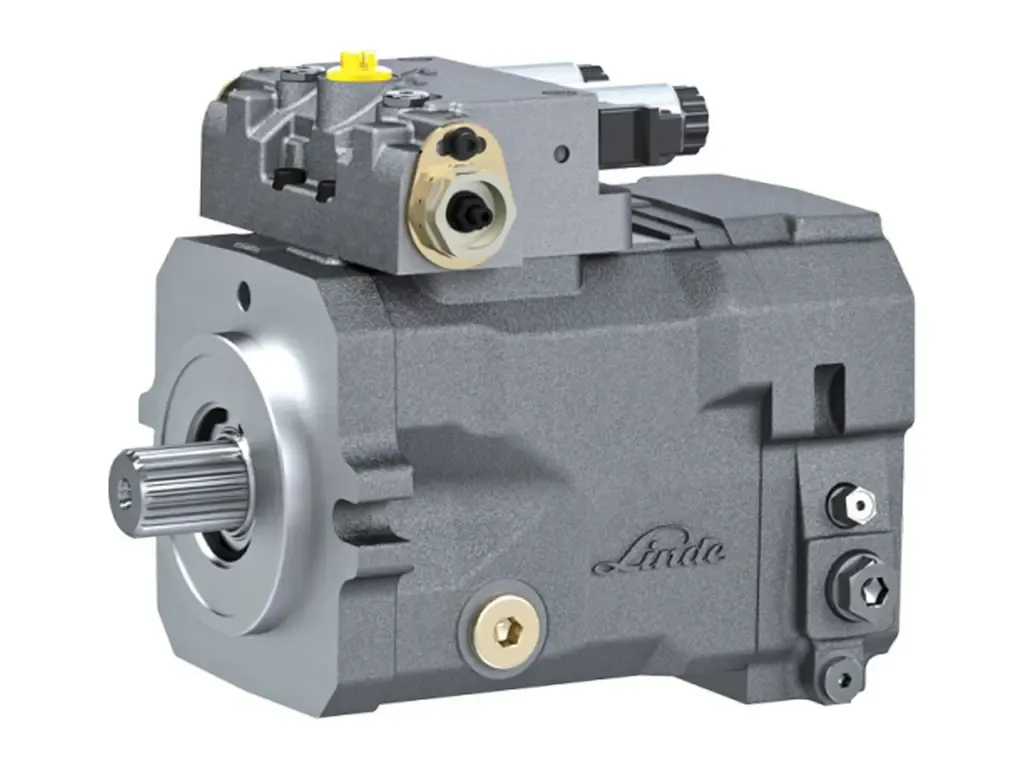

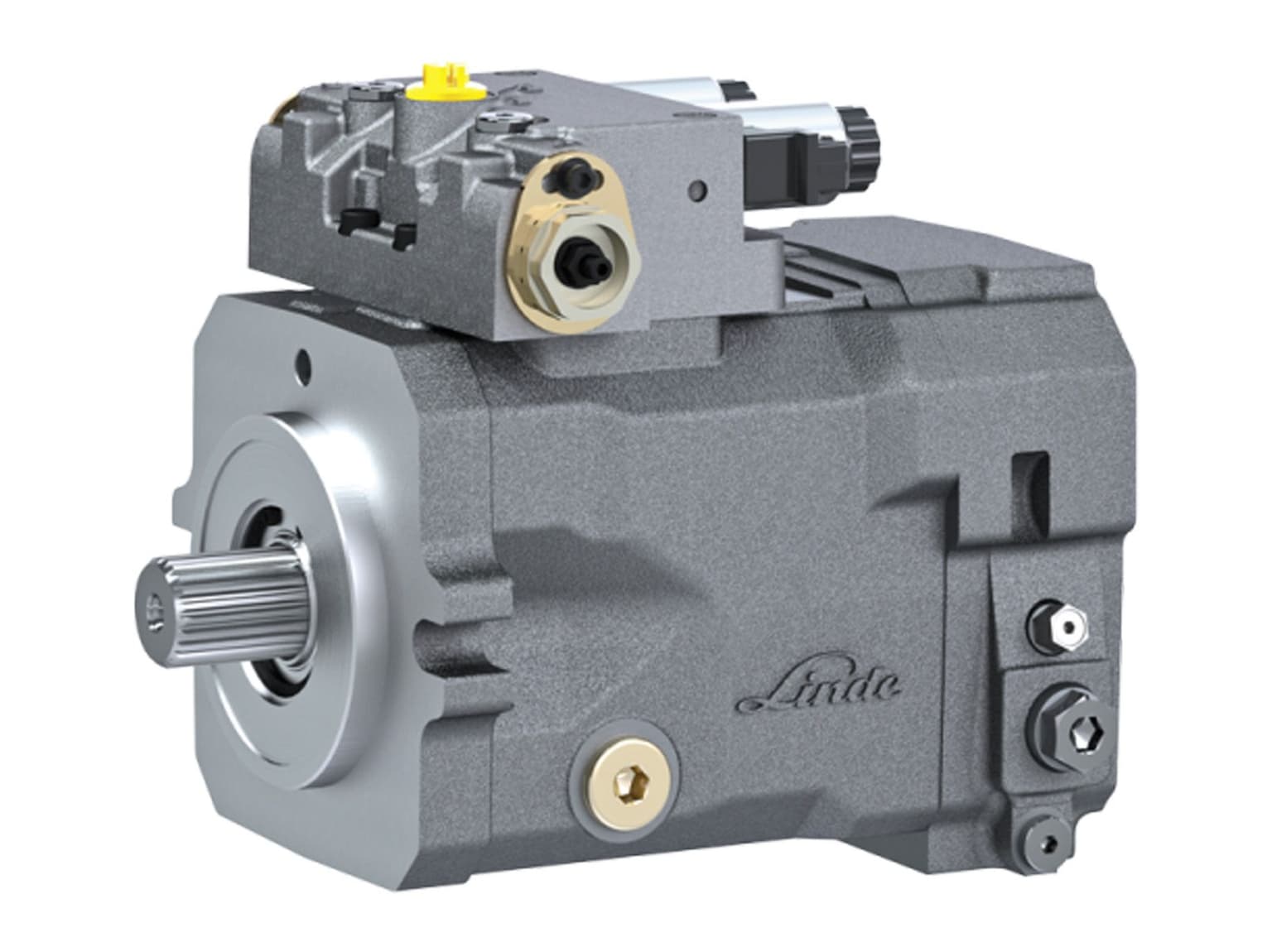

Pumps

A hydraulic pump can pump hydraulic oil to then set hydraulic motors or cylinders in motion. In doing so, the pump converts the required mechanically rotational energy into hydraulic energy in the form of volume flow and pressure. In this process, the resistance encountered by a hydraulic motor or cylinder causes the back pressure against which the pump must operate. Hydraulic pumps are essential for many applications in industry, construction, agriculture, shipping and other areas where powerful and controlled movement is required.

Which pump do you need?

Check out our product brochures for more information!

Advantages of a hydraulic pump

1. Transmission of power

Hydraulic pumps provide the power needed to drive hydraulic cylinders, motors and other actuators. This makes it possible to lift heavy loads, move machinery, operate tools and much more!

2. Build pressure

Hydraulic pumps increase the pressure of the hydraulic fluid in the system. This high pressure is used to perform work such as: gripping heavy loads, pressing materials or driving hydraulic motors.

3. Controlling speed and power

Adjusting the pump output or pressure of the hydraulic pump allows operators to control the speed and power of a hydraulic system. This provides precision and versatility in various applications.

4. Strengthening mechanical movement

Hydraulic pumps are often used in conjunction with hydraulic cylinders to generate mechanical motion. For example, a linear motion for lifting an excavator arm. Or a rotary motion to drive wheels.

Always a pump for every situation

There are different types of hydraulic pumps, such as: gear pumps, plunger pumps and piston pumps. The type of pump used depends on the specific requirements of the hydraulic system and application.

In essence, a hydraulic pump provides hydraulic systems with the power and control they need to perform various tasks. By putting fluid under pressure and using that pressure effectively to generate mechanical motion.